Each step of this process is overseen with care to craft top quality ceramic tiles that will last a lifetime.

There are many companies out there that claim to have handmade ceramic tile. But few can claim to be handmade by the actual hand of an artist. Here at Fire Creek, one artist creates every Fire Creek Artisan tile by hand. From a lump of clay to the finished piece that arrives at your doorstep.

- It begins with a thought, an inspiration or an experience, usually inspired by wildlife and nature. A drawing of a carefully detailed depiction is made in my sketchbook. After perfecting the drawing, it gets traced onto construction plastic. The plastic copy is placed on a slab of clay and traced over with a stylus to make an imprint on the slab of clay beneath.

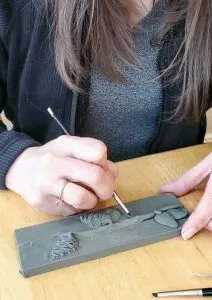

- Once the design is copied, the plastic is removed, and the carving begins. Small loop tools, dental tools and rubber tips tools, help bring the design into relief, creating hills and valleys to bring the design to life. Once the carving is complete, a plaster cast is made of the original tile. The intricacy and size of the tile determine how long it takes to carve the original tile; some tiles can take a few hours, and some can take several days to complete.

Carefully crafted, one tile at a time. That’s how handmade tile is made…

The plaster mold dries for 24-48 hours. When the mold is dry, stoneware clay is pressed into the mold. After scoring the back of the tile, the tile is stamped with the Fire Creek logo. The mold is set aside while the plaster pull moisture from the clay. This allows the tile to release easily from the plaster.

- The plaster molds dries for 24-48 hours and when the mold is dry, stoneware clay is pressed into the mold. I score the back of each tile and stamp it with the Fire Creek logo. The mold is set aside while the plaster pulls moisture from the clay. This allows the tile to release easily from the plaster. Now out of the mold, the tile dries slowly on a wire rack. Tiles can take several days to a week to dry, depending on the humidity and the temperature.

Fire Creek handmade tiles are suitable for installation anywhere in your home.

- Once the tile is bone dry, they are loaded into the kiln for their first firing. The bisque firing slowly raises to temperatures of 1881 degrees, reaching full temp about 13 hours from start to finish. The kiln is allowed to cool, which takes roughly another 13 hours, before unloading the kiln.

- Tiles are hand painted using underglazes and then a clear glaze is applied to the tile before putting the tiles back into the kiln for their final firing. This time, the temperatures get as hot as 2170 degrees, which takes about 9 hours to reach full temperature. After the kiln is allowed to cool for roughly 9 hours, the kiln is opened to reveal the beautiful, handmade artisan

Rooted in Tradition, Crafted with Love.

As you can see, the Fire Creek tile process, though lengthy, lends to beautiful, unique and durable hand-crafted tiles. It can take 6-8 weeks from drawing the design to a completed tile. The artist lovingly handles each tile through every step of the process. You will not find a C & C machine here to craft Fire Creek designs!

The hope is that each piece ignites a wonder of nature and encourages curiosity of the natural world. Fire Creek tile brings joy and serenity of the wild into your home. I want to help you live in a home that reflects your authentic self, contact me today!